In a constantly evolving world, innovative techniques for quick and efficient installation are more than ever at the heart of concerns for professionals in the construction sector. This article aims to explore the various methods and tools that help improve speed and efficiency when installing materials. We will cover concrete techniques, practical tips, and the impact of new technologies. By following these recommendations, every professional will not only be able to optimize their work but also ensure flawless quality in their projects.

Installation techniques are constantly evolving to meet growing demands for speed and efficiency. Among these innovations, the use of prefabrication methods enables elements to be prepared off-site before their installation. This significantly reduces installation time on the jobsite while minimizing disruptions.

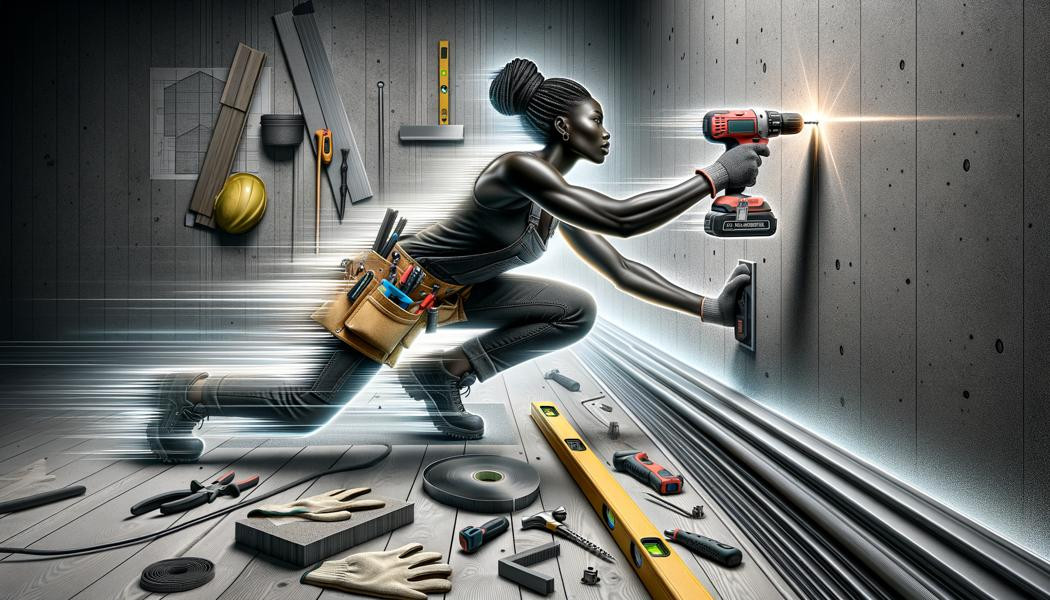

Furthermore, the use of automatic fixing systems represents a significant advance. By streamlining the fixing process, these systems allow workers to work more quickly without compromising on installation quality. By combining suitable power tools, it is possible to achieve increased efficiency while limiting the risk of human error.

Additionally, the integration of self-adhesive materials simplifies the installers’ task. These materials, which do not require traditional gluing, allow a quick application without drying time. Professionals can thus complete their works in a shorter time frame.

Finally, the use of computer-aided design (CAD) software is becoming essential. These tools allow precise planning of installations before execution, which helps anticipate problems and optimize work processes on site.

Prefabrication is a method that allows the creation of components in a factory, thus reducing on-site assembly time. This not only optimizes installation time but also ensures superior manufacturing quality.

These automated systems reduce workers’ physical efforts and speed up the fixing process, while ensuring remarkable assembly accuracy.

The choice of tools for efficient installation is a crucial step to ensure the success of any project. It is important to assess the specific needs of the jobsite before investing in any equipment. For example, high-quality drills and screwdrivers can considerably reduce working time while ensuring a neat finish.

It is also essential to prioritize ergonomic tools to minimize worker fatigue. Models equipped with non-slip panels or adjustable handles are often preferable, especially in prolonged use.

Moreover, the use of circular saws and adapted wood chisels for precise cuts is beneficial, especially in projects that require frequent adjustments. Adequate tools help improve the precision and quality of the final work.

Finally, do not overlook safety tools such as gloves, goggles, and hearing protection. Good site safety is essential and contributes to the selection of suitable working equipment.

Choosing ergonomic tools reduces the risk of musculoskeletal disorders and improves user comfort during installation.

Each type of material may require specific tools. For example, plastic, wood, and metal require adapted equipment to optimize installation quality.

To ensure quick and efficient installation, it is essential to follow well-defined key steps. First, thoroughly preparing the work plan is fundamental. This includes checking the location, taking accurate measurements, and preparing the surfaces to be treated.

Next, gathering all required materials and tools before starting helps avoid interruptions. Once the site is organized, proceed with the installation following the specific instructions for each product used—this is essential to guarantee installation durability.

Also, involving team members in proper communication is key. This ensures everyone knows what to do, thus minimizing potential errors and increasing productivity.

Finally, a final check of each step after installation is necessary to ensure everything has been done according to the required quality standards.

This step includes planning, measurement checking, and setting up equipment before installation.

An inspection after installation ensures that all aspects of the work have been carried out correctly and up to standard.

The choice of materials is critical to successful fixing. For example, premium quality screws and plugs guarantee better grip and durability over time. Using specialized adhesives adapted to different materials, such as concrete or wood, also achieves optimal results.

It is also advised to use insulating panels, which, in addition to making fixing easier, also contribute to the building’s energy efficiency. Materials like reinforced plaster or polystyrene-based panels are particularly suitable for various applications.

The flexibility of materials used can also play a significant role during installation. Composite materials, for instance, combine lightness and strength, making them easier to transport and use on site.

Finally, always consider the environmental impact of the selected materials, prioritizing sustainable products and eco-friendly choices, thus reflecting a commitment to sustainable development.

Choosing certified fixing elements is crucial for ensuring the safety of structures and prolonging their lifespan.

Opting for environmentally friendly materials meets the growing demand for sustainability in construction.

Technological advances play a decisive role in the evolution of fixing methods, making processes more efficient and faster. Using cutting-edge tools, such as high-precision wireless drills, makes tasks on-site easier.

In addition, modeling software allows for predicting fixing requirements before actual execution of work. This helps to plan purchases and reduce waste, while preparing more organized and less chaotic worksites.

The technology of the materials themselves has also evolved. Modern adhesives have greatly improved bonding properties, allowing for strong assemblies in less time. Similarly, fast-drying products are increasingly common, facilitating rapid application.

Finally, digital platforms make it easier for professionals to receive ongoing training, keeping them always up-to-date with the latest innovations and techniques in the installation sector.

Digital tools make it possible to optimize resource planning and management on the worksite, saving time and increasing efficiency.

Innovations in adhesive products make it possible to obtain more reliable and long-lasting results in reduced time.

Preparing the surface before installation is a crucial step. If the surface is inadequate, this can cause failures in fixing and compromise the durability of the materials. A clean and smooth surface ensures better adhesion.

Additionally, possible use of primers on surfaces can greatly improve the adhesion of the materials used. These products create an even layer that enhances the fixing of elements.

It is also crucial to evaluate how materials react to changes in temperature and humidity. For example, in humid environments, specific treatments must be applied to ensure lasting fixing.

Lastly, carrying out regular checks before each operation helps anticipate potential complications and enables adaptation of methods to the specific jobsite requirements.

Good analysis of surfaces allows necessary treatments to be identified before starting installation.

Specific pre-installation treatments foster better adhesion and extend the lifespan of installations.

Optimizing drying and setting times is key to speeding up installation. Fast-drying products should be prioritized. These materials, designed to minimize waiting time, allow you to move on to the next step more quickly.

Moreover, controlling environmental factors like temperature and humidity positively impacts drying time. Working under optimal conditions improves application quality and reduces delays.

Other techniques, such as the use of temporary heaters or ventilation equipment, create a more favorable environment for rapid drying of materials without altering their performance.

Lastly, adhering to the manufacturer’s recommended setting times is crucial to long-term durability of installations.

These materials are revolutionizing the sector by making work easier and dramatically reducing completion times.

Creating a favorable working environment improves installation quality.

To avoid common installation errors, it is fundamental to thoroughly read the manufacturer’s instructions. A sound understanding of processes and materials anticipates challenges and allows you to handle them appropriately.

Also, planning tasks according to each team member’s skills helps to reduce the risk of mistakes. Assigning specific tasks based on strengths optimizes overall performance.

Getting constant feedback on completed work is also advantageous. This helps detect anomalies quickly and correct them before they become major issues.

Finally, paying close attention to details such as adjustments and alignments can make a substantial difference to the quality of the finished installation.

Open dialogue among team members minimizes error risks and improves productivity.

Frequent checks of completed work enable quick detection of possible issues and guarantee quality results.

To guarantee a perfect finish after fixing, it is essential to carry out a full quality control. This involves a thorough check of every joint and connection to ensure they meet standard requirements.

Additionally, surfaces should be cleaned after installation to remove any leftover materials. This ensures a neat final presentation.

The application of finishing coats, such as paint or varnish, also plays a key role, not only for aesthetics but also for material protection. By following the manufacturer’s recommendations, you ensure these treatments are correctly applied.

Finally, communicating with the client about the operation and maintenance of the completed work is crucial for their long-term satisfaction.

Carrying out end-of-work controls ensures optimal compliance with project expectations.

The finishing techniques used can determine the final appearance and protection of materials.

Site safety is paramount, encompassing every stage of installation. Using appropriate protection, such as helmets, gloves, and safety glasses, is a necessity for every professional.

Regular training on best safety practices helps raise team awareness and reduce accident risks. By creating a safety culture, workers’ health is protected while ensuring compliance with current standards.

Furthermore, the right to withdraw and clear signaling of danger zones play a crucial role in jobsite safety. Ensuring good visibility of risks and restricted zones helps lower the incident rate.

Finally, appreciating the impact of the work environment on safety is essential. By organizing the worksite, providing enough circulation routes, and avoiding clutter, risks of accidents are minimized while increasing efficiency.

Informing teams about risks and best practices is essential for preventing workplace accidents on the jobsite.

Proper marking helps prevent injuries and reminds everyone of hazardous areas.

Feedback from professionals in the sector is often rich in lessons. Many testify to the effectiveness of modern techniques, especially the use of automated fixing systems that ensure not only time savings but also unrivalled precision.

Thus, several companies have increased their competitiveness by integrating digital tools for worksite management, enabling better planning and need anticipation. Regarding materials, the adoption of quick-drying products is also much lauded for its direct impact on project timescales.

Case studies also show that prefabrication techniques have allowed many projects to be completed in record times, while improving the general quality of structures. This demonstrates the importance of keeping up with trends and daring to innovate.

Finally, professionals highlight the necessity to keep training and sharing experiences at trade shows or professional conventions, to stay on top of the sector’s best practices.

Projects that have integrated innovative solutions illustrate how the adoption of new techniques has transformed worksites.

Regular skills updates are crucial for thriving in a constantly evolving market.

Trends in the field of installation are evolving rapidly, influenced by technological innovation and environmental concerns. More and more, sustainable and eco-friendly materials are favored by both consumers and professionals.

Meanwhile, the use of augmented reality to present projects to clients before realization is booming, enabling better interaction and understanding of projects.

Safety standards are also becoming stricter, making it essential to integrate robust solutions adapted to working conditions. These changes require professionals to adapt their methods to meet these new standards.

Finally, training and certifications specific to new technologies and methods are gaining in popularity, enabling workers to improve and broaden their skills.

The choice of materials and techniques is shifting towards more environmentally friendly options, reflecting a growing demand for eco products.

The integration of digital tools and new working methods is transforming the way installation projects are designed and managed.

In conclusion, innovative techniques for quick and efficient installation are in constant evolution. The choice of tools, materials, and compliance with key steps are decisive for the success of every project. Safety remains a top priority, and the importance of continuous training cannot be underestimated. Lastly, staying on top of trends allows not only staying competitive but also offering high-quality services adapted to new market demands.

Whether you need fast help or want to offer your services, Helplease is your solution! Download the app to access qualified experts or find clients in just one click, and simplify your daily life! Available on iOS and Android!