In a world where furniture is rapidly evolving, it is crucial to explore the furniture assembly techniques that are on the horizon for 2025. This article will guide you through the emerging trends, innovative tools, the influence of technologies, and revolutionary materials that will redefine our way of assembling furniture. Furthermore, we will address sustainable practices, common mistakes to avoid, and ergonomic innovations that will ensure not only beautiful aesthetics but also optimal use. By understanding these aspects, we will be able to prepare for a future where furniture assembly is easier, sustainable, and accessible to all.

Do you need help assembling your furniture? Quickly find a qualified service provider on Helplease and benefit from a tailored service to meet all your needs. Discover professionals near you!The trends in furniture assembly for 2025 show a strong inclination towards automation and the use of lightweight materials. This will not only reduce the weight of furniture but also simplify the assembly processes. Additionally, many brands are moving towards modular designs that allow consumers to customize and assemble their furniture according to their specific needs.

We are also seeing a growing interest in multifunctional furniture that can adapt to various spaces and uses. This is particularly relevant in urban areas where space is limited. Designers are beginning to integrate folding or storage mechanisms into their creations, making assembly less cumbersome.

Environmental respect also plays a critical role in these trends. Consumers are becoming increasingly demanding regarding the durability of the materials they choose. As a result, manufacturers must rethink their methods to include recycled or recoverable materials, which requires innovation in furniture assembly by offering solutions that are both aesthetic and eco-friendly.

Finally, digitalization has paved the way for new design and assembly tools, stimulating increased competition in the industry. 3D modeling software is gaining popularity, allowing designers to easily create customized furniture while facilitating its assembly.

Professionals, are you looking for more clients? Sign up on Helplease today to offer your services and grow your business. Access a large client base in just a few clicks!In the digital age, the furniture sector is witnessing a true revolution thanks to innovative tools that make assembly faster and more efficient. Electric screwdrivers equipped with intelligent guidance systems and high-performance cordless drills have now become essentials for assemblers, whether they are professionals or amateurs.

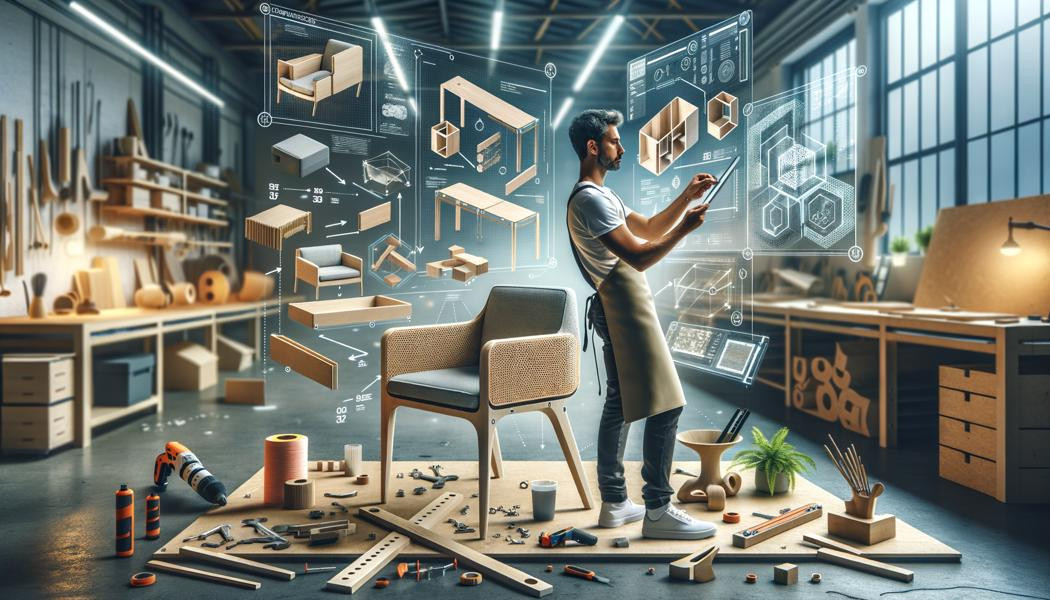

At the same time, technologies such as augmented reality are on the rise. This type of technology allows users to visualize assembly instructions in real-time on their smartphones or tablets, making the process more interactive. Users can see in 3D how to assemble each element without getting lost in complex instructions.

Additive manufacturing tools, or 3D printing, are also becoming increasingly common. These tools allow for the production of custom parts that can fit perfectly with the rest of the furniture, reducing the need for tuning and adjustments after assembly. This opens the door to even more personalized designs for consumers.

Finally, digital platforms incorporating voice commands or connected applications are also gaining momentum. These applications allow for complete control of the assembly process by guiding the user with precise instructions tailored to their skill level.

If you are looking for an expert to meet your specific needs, visit Helplease and discover the available providers near you. Make your life easier and find the right professional!Technology is radically transforming furniture assembly methods, making the process faster, more precise, and often effortless. One of the most significant innovations is automation, which allows the use of robots to assemble furniture components with impressive precision. This not only reduces human error but also increases production speed.

Moreover, computer-aided design (CAD) software allows designers to model furniture in 3D before it is even produced. This not only facilitates the identification of potential assembly problems but also the creation of assembly mechanisms that optimize space and functionality. By integrating customer feedback into these designs, companies can offer furniture tailored to market needs.

New digital platforms offer the possibility to create interactive content to guide users through the assembly process, making instructions clearer and more understandable. These applications can also assess the user's skill level and adapt recommendations accordingly, which is particularly beneficial for less experienced users.

Finally, the development of 3D printing technologies allows manufacturers to produce spare parts for furniture, facilitating maintenance and longevity of products. On-demand printing means less waste and a more sustainable approach.

The materials used in furniture assembly are undergoing a profound change with the emergence of innovative composites that combine lightness, durability, and aesthetics. Biodegradable plastics and cellulose-based composites are increasingly favored for their environmentally friendly properties, offering an alternative to traditional materials like wood or metal.

Smart materials with adaptive properties will also make their appearance. For instance, components that automatically adjust based on temperature or humidity will provide added comfort while adopting an adaptive approach. These smart materials can also contribute to durability by reducing the need for frequent repairs.

Furthermore, lightweight metals and alloys combining multiple elements to strengthen robustness without adding extra weight are emerging in the market. These materials will reduce potential shipping costs and simplify assembly processes without compromising quality.

Finally, the focus on durability is prompting more manufacturers to explore the use of recycled or recoverable materials. This not only provides a competitive edge in the market but also fosters a reduced ecological footprint for the industry.

Sustainable assembly techniques play a vital role in the design and manufacturing of eco-friendly furniture. For example, snap-fit assembly methods that require no screws or glue are valued for their recyclability and low environmental impact. These techniques allow furniture to maintain its structural integrity while facilitating disassembly at the end of its life.

Similarly, using eco-friendly adhesives made from natural resins represents another significant advancement. These adhesives not only have a reduced chemical footprint but also ensure comparable lasting performance to traditional adhesives.

In the same vein, brands are beginning to experiment with cold assembly, which uses pressure rather than heat to join materials. This reduces energy requirements while providing robust joints, particularly for wood and composites.

Implementing products with recognized environmental certifications, along with transparency regarding manufacturing processes, is also becoming essential. This gives consumers assurances about the durability and compliance of the products they purchase.

Applications and software play a considerable role in optimizing furniture assembly processes. With intuitive digital platforms, users can now access step-by-step instructions and explanatory videos, making furniture assembly simpler and less intimidating. Augmented reality, for example, allows users to overlay 3D models onto real surfaces, guiding them through their montages.

Inventory management is also improved by using dedicated software that analyzes consumption trends and prevents stockouts. These applications allow for proactive planning, reducing waste and increasing operational efficiency.

Collaborative design software finally allows design teams to work together in real time, regardless of geographic location. This improves communication and allows for the quick identification of necessary adjustments, which can significantly reduce time to market.

By integrating databases and artificial intelligence systems, these applications can also anticipate consumer needs and adapt offerings, maximizing customer satisfaction.

Furniture assembly, although often perceived as a simple process, can involve several pitfalls to avoid. Among the frequent mistakes, not carefully reading the instructions is one of the most common. This can lead to poorly assembled parts or considerable time losses.

Next, neglecting to gather all necessary tools and components before starting the assembly can also cause inconveniences. Having all materials on hand allows for a certain flow during the process and avoids unnecessary interruptions.

Another mistake is forcing pieces that seem not to fit perfectly. This can damage materials or lead to long-term complications. It is essential to respect fittings and ensure that each element fits properly without excessive pressure.

Finally, for those assembling multiple pieces of furniture in succession, it is vital to maintain good organization. Disarray or confusion between parts can lead to mistakes in later assemblies, complicating the overall process.

New furniture assembly methods significantly contribute to their durability. By integrating modular systems, furniture can be adapted based on usage requirements, thus reducing the need for spare parts or frequent repairs.

Glue-free techniques, such as grooving or interlocking, minimize the use of chemical substances, which reduces environmental impact and toxicity related to furniture disassembly. This contributes to an eco-friendly approach while increasing recyclability.

New materials and innovative coatings, which offer increased resistance to elements such as water and scratches, also prolong the life of furniture, making their use more sustainable in the long term. These innovations enhance consumer satisfaction by ensuring more reliable products.

Ultimately, introducing technology into assembly allows for the design of furniture that adapts to ambient conditions, such as humidity and temperature variations, thereby increasing product longevity.

Ergonomic aspects are essential during furniture assembly, as they ensure not only user comfort but also increased safety. On one hand, it is important to ensure that furniture is designed so that it can be assembled without causing physical strain or undue fatigue. This includes the height of assembly surfaces and assembly angles.

On the other hand, using lightweight yet robust parts allows for easier transport during assembly, which reduces the risk of injury. Tools with ergonomic handles further enhance the user experience, making assembly more comfortable.

Furthermore, ensuring that assembly instructions are clear and understandable also contributes to an ergonomic approach. Well-written guides prevent frustrations and promote safe assembly.

Finally, practitioners should take into account the perspectives of end-users to ensure that the furniture ultimately meets their ergonomic and comfort needs, both during use and assembly.

Innovations in design are radically impacting the furniture assembly process. Today, designers are pushing boundaries by incorporating new shapes and structures that facilitate assembly while remaining aesthetically pleasing. The goal is to create unique pieces that appeal visually without compromising functionality.

Modular and customizable designs are becoming the norm. They allow customers to adapt their purchases to their living space while simplifying assembly methods as it is possible to assemble only the necessary parts at first, with others being added later if needed.

Additionally, designers are increasingly interested in the environmental impact of their creations. By choosing sustainable materials and innovative sewing or fastening techniques, they manage to design furniture that respects both aesthetic and ecological requirements.

Finally, the trend towards sharing digital experiences is leading to furniture designed to interact and integrate in a high technology environment. Furniture with built-in connections or wireless chargers further roots the importance of contemporary design in assembly.

Furniture assembly training is greatly benefiting from technological advances. Today, schools and training centers are adopting online teaching techniques, allowing learners to take furniture assembly courses at their own pace. Learning management platforms offer interactive modules, making the process more engaging.

Moreover, augmented reality simulations provide students with the opportunity to practice furniture assembly in a virtual environment before entering the real world. This allows them to familiarize themselves with tools and techniques without risking damage to real furniture.

Online events such as webinars enable trainers to integrate live content that expands knowledge, as well as introduce industry experts as speakers. This helps bridge theory and practice, enriching the learning experience.

Finally, mobile applications offer the general public learning resources for furniture assembly, thus broadening access to education and making practical learning more accessible than ever.

The forecasts for the furniture assembly market indicate a significant growth potential due to the increasing demand for customizable and practical products. Consumers are increasingly turning towards modular furniture that is easy to assemble and move, in response to a dynamic lifestyle.

Studies also indicate that the digitization of retail operations, combined with the rise of e-commerce, will boost demand for assembly services at home. Companies investing in automated assembly options will be better positioned to capture a share of the expanding market.

The growing environmental awareness will also drive the market towards sustainable assembly techniques and materials, requiring adjustments in business strategies. Manufacturers will need to respond to these new consumption trends by offering eco-friendly products while ensuring the performance promised by their designs.

In conclusion, the furniture assembly market is constantly evolving, with technological advancements, environmental concerns, and consumption preferences shaping the landscape of the future.

In summary, the furniture assembly techniques in 2025 are oriented towards a fusion of innovation, sustainability, and customization. From the use of advanced technologies to revolutionary materials, each element contributes to enhancing user experience. The common mistakes to avoid, as well as ergonomic considerations, should not be overlooked to ensure a smooth assembly and functional furniture. This promising market underscores the necessary shift in our approach to furniture, combining aesthetics and practicality in response to contemporary challenges. At the dawn of this new era, it will be fascinating to follow the evolution of assembly trends and see how they transform our way of living and working with furniture.

Whether you need quick help or wish to offer your services, Helplease is your solution! Download the app to access qualified experts or find clients with a click, and simplify your daily life! Available on iOS and Android!